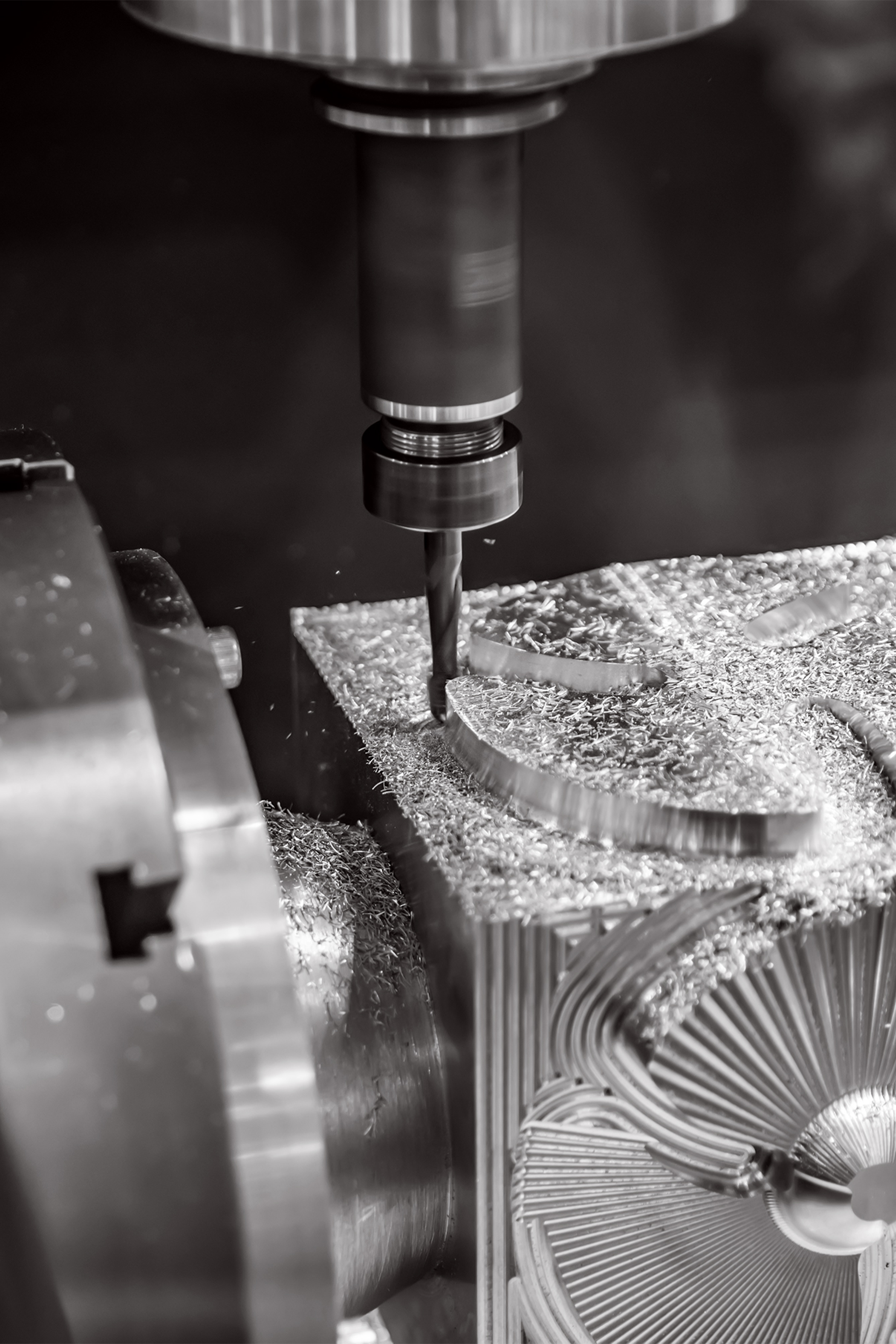

CNC MACHINING

CNC machining is pivotal in modern manufacturing, creating intricate parts with unparalleled precision and repeatability. Through techniques like turning, drilling, and multi-axis milling, we translate your designs into top-quality parts.

Flexibility and consistency across diverse applications

Turning, Drilling, and Multi-Axis Milling

Extensive Material Options and Fast Lead Times

Precision Tolerances to +/-0.001 Inches

Precision CNC Machining

We utilize advanced CNC technology and CAM systems to deliver exceptional precision in every project, meeting even the most demanding specifications. Our highly trained technicians and machinists are dedicated to flawless results, adhering to strict quality control measures throughout the process. We offer quick prototyping and on-demand low-volume production, helping you meet market demands efficiently.

- CNC Milling

- CNC Turning / Lathe

- Auto Lathe

- EDM (Sinker, Wirecut & Super Drill)

- Gear Hobbing, Shapper

- Surface Grinding

Post Processing

- Case Hardening

- Deburring

- Heat Treatment

- Part Marking

- Product Assembly

- Precision Grinding

- Press Fitting

Surface Finishing

- Electroplating (Anodising, Black Oxide, Electroless Nickle, Hard Chrome, Zinc Plating, passivation & more)

- Electropolishing

- Coating (Powder coating, Spray painting & more)

- Sandblasting / Bead blasting

- Tumbling

- Mechanical grinding, brushing, polishing and buffing

Material Versatility

We work with a diverse range of materials, including:

| Metals | Plastics | Exotic Alloys |

|---|---|---|

| Aluminium | ABS | Titanium |

| Steel | Polycarbonate | Inconel |

| Stainless Steel | Nylon | |

| Brass | Peek | |

| Copper |

Size Limitations

Though CNC machining boasts versatile multi-axis milling capabilities including turning, drilling, and complex machining processes, size limitations may arise. For larger projects, fret not! Reach out to us, and we'll explore alternative solutions or collaborate with trusted specialists to fulfill your requirements.

| CNC Machining | Conventional Machining | |

|---|---|---|

| Maximum Part Size | 1600mm x 800mm x 800mm | 800mm x 400mm x 400mm |

| Minimum Part Size | 0.5mm | 1mm |

| Minimum Part Diameter | Ø0.5mm | Ø5mm |

| Maximum Part Diameter | Ø240mm | Ø2600mm |

*CNC Machining default general tolerances refers to ISO 2768-mK

*Larger parts are reviewed on request, submit a RFQ to begin

Quality Control

To be the best, we consistently ensure that our quality is never compromised. We implement rigorous checks throughout the entire process to maintain our standards.

01

Material Checkup

We verify the materials meet your project's exact specifications before we begin.

02

Constant Monitoring

Throughout production, our team keeps a watchful eye on the parts, ensuring everything is on track.

03

Final Inspection

Before anything leaves our facility, it undergoes a final comprehensive inspection to guarantee the highest standards.

Typical Applications of CNC Machining

CNC machining's true power lies in its diverse range of applications. Here at Mixxion, we leverage this technology for a variety of purposes: